Fabric shrinkage is a common phenomenon in textiles, yet many people remain unaware of its implications. For manufacturers, designers, and even consumers, understanding shrinkage is essential for ensuring product quality and customer satisfaction. A reliable fabric shrinkage tester is the key tool for determining shrinkage rates and maintaining high-quality standards.

What is Shrinkage in Textile?

Shrinkage refers to the reduction in the dimensions of a fabric after it has been washed, dried, or exposed to moisture and heat. This occurs when the fibers in the fabric return to their natural state, having previously been stretched or manipulated during the manufacturing process. While a small amount of shrinkage is normal, excessive shrinkage can negatively impact the usability and appearance of garments.

For example, imagine purchasing a perfectly fitting shirt, only to find it too tight after its first wash. This is a classic case of shrinkage in textiles that manufacturers strive to prevent by using precise testing methods.

Causes of Fabric Shrinkage

- Fiber Type

Different fibers behave differently when exposed to moisture and heat. Natural fibers like cotton and wool are more prone to shrinkage than synthetic fibers such as polyester or nylon. - Fabric Construction

The weave or knit structure of a fabric can influence its likelihood to shrink. Loose weaves are more susceptible to dimensional changes than tightly woven fabrics. - Finishing Processes

Manufacturing processes like dyeing, bleaching, and heat treatments can affect the stability of fabrics, potentially leading to shrinkage.

Importance of Measuring Shrinkage

Understanding shrinkage levels is critical for textile manufacturers. Excessive shrinkage can lead to product recalls, customer dissatisfaction, and reputational damage. Measuring and controlling shrinkage ensures that fabrics meet industry standards and perform as expected during use.

This is where tools like the fabric shrinkage tester come into play. By accurately assessing shrinkage rates, manufacturers can make informed decisions about fabric treatments, improve product quality, and reduce returns.

How Does a Fabric Shrinkage Tester Work?

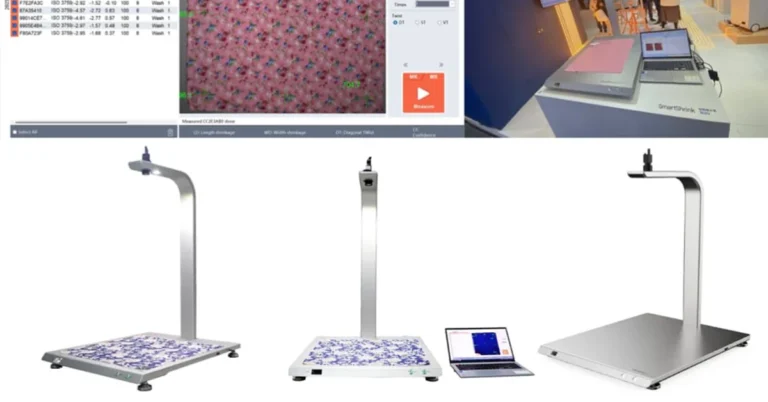

A fabric shrinkage tester, such as the SmartShrink Shrinkage Rate Tester, is a specialized device used to measure the dimensional changes in textiles. The process typically involves:

- Marking the Fabric

A sample piece of fabric is marked with precise measurements before testing. - Subjecting the Fabric to Conditions

The fabric is washed, dried, or exposed to specific environmental conditions that simulate real-world usage. - Measuring the Results

After treatment, the tester calculates the percentage change in the fabric’s dimensions, providing a clear shrinkage rate.

Benefits of Using a Fabric Shrinkage Tester

- Accurate Results: The SmartShrink Shrinkage Rate Tester provides precise measurements, allowing manufacturers to confidently address shrinkage issues.

- Enhanced Product Quality: By identifying fabrics prone to shrinkage, manufacturers can take preventive measures to improve durability and performance.

- Cost Savings: Reducing returns and complaints saves money and protects the brand’s reputation.

- Compliance with Standards: Many industries require fabrics to meet strict shrinkage limits, and a tester ensures compliance.

Why Choose the SmartShrink Shrinkage Rate Tester?

The SmartShrink Shrinkage Rate Tester is an industry-leading tool designed for accuracy and reliability. It is user-friendly, efficient, and built to handle a wide range of fabric types. Whether you’re a textile manufacturer or a quality control professional, this tester helps you maintain the highest standards in your products.

Conclusion

Shrinkage in textiles is a crucial factor that affects both fabric quality and customer satisfaction. Understanding what shrinkage in textile entails and using tools like the fabric shrinkage tester ensures that fabrics meet performance expectations. By investing in advanced solutions like the SmartShrink Shrinkage Rate Tester, businesses can maintain superior quality control and stay ahead in the competitive textile industry.