When it comes to measurements and materials in various industries, precision and clarity are essential. One such specific measurement that often comes up in technical fields is 4.579 mm. The term “4.579 mm solid” can be used to describe a solid object or material that has a thickness or diameter of 4.579 millimeters, and understanding its significance, context, and uses can offer insights into a variety of applications. This article will explore what 4.579 mm solid refers to, the key insights surrounding it, and its common uses in industries ranging from manufacturing to electronics.

TRENDING

What Is It Called Animacinema? Discover The Art Of Animacinema

What Is 4.579 mm Solid?

Before diving into the key insights and uses, it’s important to understand exactly what “4.579 mm solid” means. In the simplest terms, it refers to a solid object or material that measures 4.579 millimeters in a given dimension—most often in terms of thickness, diameter, or length.

In industries that require precision and exact measurements, such as manufacturing, engineering, and product design, 4.579 mm may be the exact specification for components that need to fit into a larger system or serve a specific function. The term “solid” indicates that the material or object is not hollow or porous, meaning that it has a full, consistent form.

How Is 4.579 mm Determined?

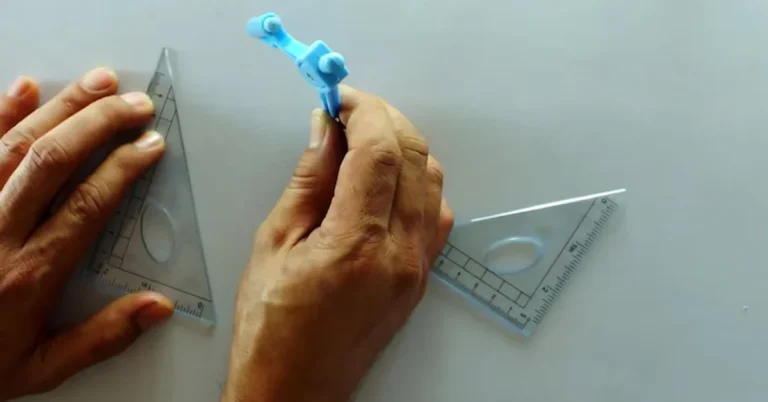

The number 4.579 millimeters is often derived through precise measurement tools, such as micrometers or calipers, and it may be a result of a detailed design process. For instance, engineers and designers might specify 4.579 mm to meet a requirement for a specific tolerance or function within a system.

Key Insights About 4.579 mm Solid

Understanding the significance of 4.579 mm solid’s involves looking at its properties, the precision it provides, and its applications across various industries. Let’s delve deeper into these aspects.

Precision Engineering

One of the most important insights into 4.579 mm solid is its role in precision engineering. Many components, especially in industries such as aerospace, automotive, and electronics, must meet strict dimensional tolerances. A tolerance of 4.579 mm is incredibly precise, allowing manufacturers to produce parts that fit together perfectly within a larger system.

For example, in the field of mechanical engineering, a component might need to be 4.579 mm thick to fit into a gear mechanism or an assembly. The precision ensures that the part operates effectively without gaps, misalignments, or friction that could cause damage over time.

Material Considerations

The material from which a 4.579 mm solid component is made is another crucial factor. Depending on the application, the material might need to possess certain properties, such as high strength, corrosion resistance, or thermal stability. Common materials that might be used for solid objects of this thickness include metals (such as stainless steel or aluminum), plastics, ceramics, and composites.

The choice of material will impact the durability, weight, and overall performance of the component. For instance, in electronics, a 4.579 mm solid plastic might be used for a protective casing, while in aerospace, a similar-sized component could be made from a lightweight but strong metal.

Tolerance and Fit

In the world of engineering and manufacturing, tolerances refer to the allowable deviation from a specified dimension. A tolerance of 4.579 mm might have a margin of error, such as ±0.001 mm, which ensures that the part will still fit and function properly within a system, even if there is slight variation in its production.

In many cases, a specific size like 4.579 mm is chosen to achieve an optimal fit between two components. This level of precision allows parts to interlock, mesh, or otherwise perform their function with minimal risk of malfunction.

Common Uses Of 4.579 mm Solid In Various Industries

Now that we’ve covered the key insights into 4.579 mm solid, let’s explore the practical applications of this measurement in different industries.

Electronics and Circuitry

In the electronics industry, precision components are crucial to the functionality of devices ranging from smartphones to computers. A 4.579 mm solid component could be used in the manufacturing of connectors, resistors, capacitors, or even the casing of a device. Such precision ensures that each part fits within the desired system and interacts as expected with other parts.

For example, a 4.579 mm solid connector pin might fit into a specific port on a circuit board, ensuring that power or data flows without interruption. The reliability of the electronics is directly tied to how well these small components are manufactured to exact specifications.

Automotive Manufacturing

In the automotive industry, 4.579 mm solid parts could be used in a variety of applications, from engine components to suspension systems. Small mechanical parts, such as bearings, bushings, or shafts, might require a precise diameter or thickness to function correctly in a vehicle.

A 4.579 mm solid steel rod, for instance, might be used as part of the gear mechanism in a car’s transmission. Its precision ensures that the gear shifts smoothly and reliably over time, contributing to the vehicle’s overall performance and longevity.

Aerospace Engineering

The aerospace sector demands extremely high levels of precision, and a small component measuring 4.579 mm solid might play a critical role in ensuring safety and efficiency. Components such as fasteners, structural supports, or even seals might need to adhere to this specific measurement.

For example, a 4.579 mm solid titanium bolt might be used to secure two parts of an aircraft’s wing, ensuring that the components are held together securely under extreme stress and pressure. The durability and precision of such a part are critical for maintaining the structural integrity of the aircraft.

Medical Devices

In medical device manufacturing, precision is paramount. A 4.579 mm solid component could be part of a medical instrument, implant, or diagnostic tool. Materials used in these devices need to be biocompatible, sterilizable, and durable.

For instance, a 4.579 mm solid titanium rod might be used in a spinal implant or prosthetic limb. The precision ensures that the device fits seamlessly into the human body and performs its intended function without causing harm or discomfort.

3D Printing and Prototyping

The rise of 3D printing has revolutionized prototyping and product development. Components with dimensions like 4.579 mm solid are often produced via 3D printing technology. This precise measurement allows for the rapid creation of functional prototypes, which can then be tested and refined for production.

Whether designing a consumer product or a mechanical part, 3D printing can create components with exact measurements like 4.579 mm to ensure that each prototype meets the necessary specifications before mass production.

Conclusion

In conclusion, 4.579 mm solid refers to a precise, solid component or material that measures 4.579 millimeters in one dimension. This specific measurement plays a critical role in industries ranging from electronics to aerospace, where precision and performance are key.

The choice of material, tolerance, and fit are crucial factors that determine how these components function within larger systems. Understanding the importance of this specific measurement is essential for engineers, designers, and manufacturers who rely on accuracy and durability to create high-performance products.

ALSO READ: What Is A Perkue Maker? Exploring Its Features And Benefits

FAQs

What is 4.579 mm solid?

4.579 mm solid refers to a component or material that is solid and measures exactly 4.579 millimeters in thickness, diameter, or length. It is used in various industries where precision is critical for performance and functionality.

Why is 4.579 mm important in manufacturing?

This specific measurement ensures that parts fit together accurately in mechanical systems, helping to avoid misalignments, poor fits, and mechanical failure. It plays a crucial role in maintaining the integrity of products in industries like automotive, aerospace, and electronics.

How is 4.579 mm measured?

4.579 mm’s is typically measured using precise instruments like micrometers, calipers, or other high-precision measuring devices to ensure that the component meets exact specifications.

What are some materials used for 4.579 mm solid components?

Materials commonly used include metals like stainless steel and aluminum, plastics, ceramics, and composites, depending on the application and required properties such as strength, durability, or weight.

In which industries is 4.579 mm solid commonly used?

Industries that frequently use this precise measurement include electronics, automotive manufacturing, aerospace engineering, medical device production, and 3D printing, all of which rely on high-precision components for their systems to function correctly.