What Is Chemical Blending?

Chemical blending is the precise process of combining two or more chemical substances to produce a uniform mixture that meets specific requirements regarding texture, reactivity, shelf life, and other functional properties. This foundational process supports everything from household cleaning products and pharmaceuticals to nutraceuticals and industrial materials. At its core, blending achieves consistency at a molecular or particulate level, ensuring that every finished product delivers reliable performance to end-users in high-stakes industries.

Leading chemical blenders utilize advanced equipment and specialty know-how to scale operations without compromising quality to accomplish such uniformity. These experts select the right technologies and protocols, accommodating the nuances of ingredient properties and regulatory demands. In competitive markets, the ability to engineer stable and safe blends is indispensable for manufacturers seeking to maintain product excellence and consumer trust.

Types Of Chemical Blending Processes

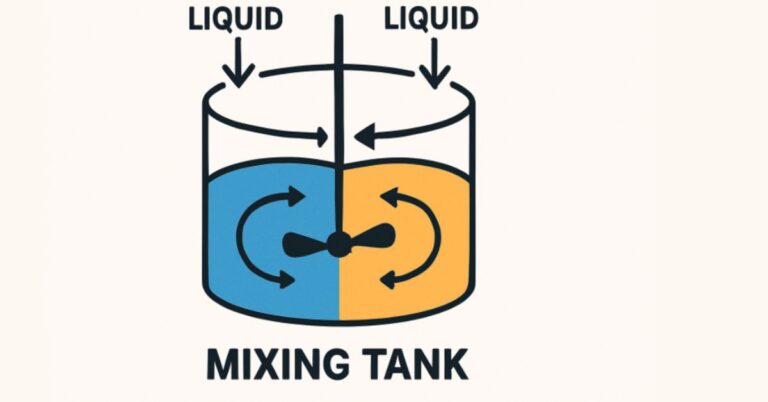

Blending processes are selected according to the materials’ characteristics and the application’s demands. The two primary methods are batch blending and continuous blending. Batch blending allows flexibility and customization—a critical feature for facilities handling diverse product lines or fluctuating order sizes. By contrast, continuous blending excels in large-scale environments, where high-volume output of a single formulation is required. This method uses sophisticated equipment to maintain uninterrupted mixing, resulting in uniform products around the clock.

Another determinant is the mixing force. Certain sensitive or viscous ingredients demand low-shear mixing to preserve delicate structures or avoid undesired reactions, whereas robust ingredients or those requiring dispersion benefit from high-shear techniques. Environmental variables such as temperature, humidity, and particulate size must also be monitored and adjusted for successful blending.

Key Benefits Of Chemical Blending

The advantages of chemical blending reach deep into the foundations of modern manufacturing. Uniform blends underpin consistent product performance—an absolute necessity in pharmaceutical industries, where every dose counts. Automation in blending processes minimizes manual intervention, reducing human error and improving repeatability. Finally, blending enables manufacturers to achieve economies of scale by utilizing raw materials efficiently, cutting both time and operational costs across the supply chain.

This commitment to efficiency and reliability is reflected in the most recent technology news, where manufacturers leverage automation and digital controls to stay ahead of industry expectations for quality and sustainability.

Importance Of Formulation Expertise

Developing a successful blended product hinges on a meticulous formulation strategy. Chemists and process engineers don’t simply choose suitable raw materials—they carefully tailor concentrations, ingredient sequences, and mixing parameters to meet performance and safety objectives. Even a minor alteration in formulation can dramatically alter the outcome, particularly for regulated industries such as food additives or pharmaceuticals.

Formulation expertise ensures that every batch adheres to strict tolerances, meeting or exceeding rigorous quality and regulatory benchmarks. This precision keeps end-users safe and reassures clients that the blend will deliver the expected results with every production run.

Quality Assurance And Safety Protocols

Vigilance in quality and safety protocols is critical in chemical blending. It starts with verifying the purity and properties of incoming materials, followed by in-process controls to monitor consistency. Analytical methods—like spectroscopy or chromatography—are applied to measure and confirm uniformity at every stage. Adhering to industry regulations, such as ISO 9001 or GMP, guarantees product safety and reliability and heightens traceability and accountability for every blend produced.

As highlighted by the global scientific community, the combination of rigorous in-house protocols and compliance with external standards delivers safe and effective products while minimizing liabilities for workers and consumers. Protecting environmental health and personal safety remains at the forefront of advanced blending operations.

Challenges And Solutions In Chemical Blending

Chemical blending is not without its challenges. Variations in raw material properties, such as particle size or moisture content, can lead to inconsistent blends. Incompatibilities between ingredients may result in separation, degradation, or other quality concerns. Scaling up from pilot to full production often surfaces issues that are not apparent at smaller volumes, requiring proactive troubleshooting and process refinement.

Overcoming these obstacles demands rigorous testing at every stage, careful calibration of mixing equipment, and the integration of real-time monitoring systems that can rapidly identify—and resolve—variations. Modern facilities continue to adopt robust digital controls and sensors to track blend parameters, enabling swift corrections and reducing waste during production.

Technology And The Future Of Blending

Technological innovation is redefining chemical blending, promising unprecedented precision and control. Automation and AI-powered analytics are helping manufacturers optimize every step: from ingredient dispensing to mixing cycles, blend monitoring, and predictive equipment maintenance. These intelligent systems provide the agility to adjust processes remotely, ensuring compliance, traceability, and operational efficiency across plant locations.

As “smart” manufacturing transforms the sector, chemical blending will be central in delivering customized products on demand, fostering continued industry growth and adaptation to evolving consumer and regulatory requirements.

Conclusion: Blending For Tomorrow’s Needs

Chemical blending is a vital process that enables the creation of countless essential products, quietly supporting the needs of nearly every primary industry. As demands for quality and accountability intensify, so does the importance of investing in skilled personnel, advanced equipment, and digital innovation. For those involved in manufacturing, supply chain operations, or product strategy, a deep understanding of chemical blending’s science and processes is key to long-term success and industry leadership.