Construction sites are energizing environments where single activities are carried out simultaneously. While they are a base for building infrastructure, they also pose meaningful recourse risks to workers, visitors, and the general public. Ensuring recourse on building sites prevents accidents, injuries, and even fatalities. This guide provided primary and base recourse tips for Construction Estimating Services that should be followed to create a safe working environment on building sites.

Wear Appropriate Individual Defensive Gear PPE

Individual Defensive Gear PPE is the primary line of guard against wounds on a structure site. Laborers should wear overabundant stuff to shield themselves from adequacy perils. Some ordinary PPE incorporates:

- Caps: Shield against head wounds from falling items.

- Wellbeing Goggles: Safeguard eyes from residue, garbage, and synthetic sprinkles.

- High Visibility Vests: Ensure workers are gently seen by machinery operators or vehicles.

- Gloves: Protect hands from cuts, chemicals, and other grievous materials. Safety Boots: Reinforce shelter for feet against heavy objects and sharp debris.

Always check that the PPE is in good delineation and fit before starting work. Wearing PPE at all times is important because it reduces the risk of injuries.

Conduct Regular Safety Training

Regular recourse training is based on all workers on a building site. Even experienced workers should have attended refresher courses to stay updated on the modish recourse protocols. Training should have been covered:

- Proper use of machinery and tools.

- Emergency reaction procedures.

- How to recognize effectiveness hazards.

- Safe lifting techniques to preserve back injuries.

By ensuring everyone understands the risks and knows how to deal with grievous situations, building sites fit and are safer for all.

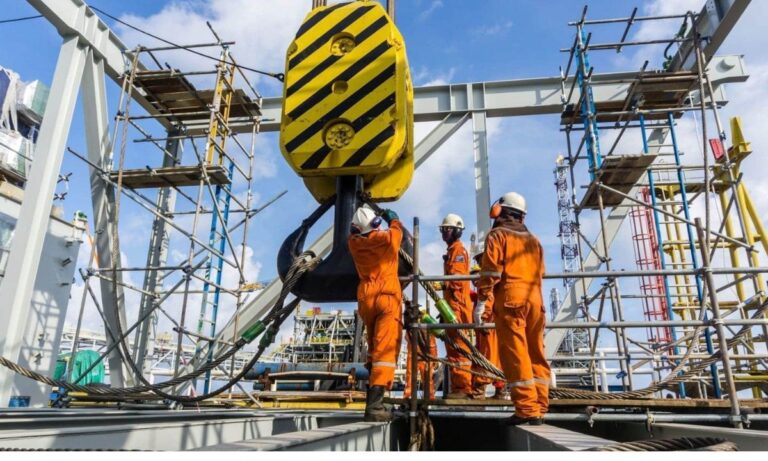

Ensure Proper Scaffolding Setup

Scaffolding is a normal building on building sites, but it can be dangerous if not set up properly. To avoid accidents:

- Inspection: Ensure scaffolding was inspected by a qualified single before use.

- Stability: Ensure it was placed on a lasting rise and secured right.

- Guardrails: Always install guardrails on scaffolding platforms to preserve falls.

- Weight Limits: Never exceed the recommended load capableness of scaffolding.

Training workers on the right setup and use of scaffolding greatly reduced the risk of falls and injuries.

Implement Fall Protection Measures

Falls are one of the leading causes of accidents on building sites. Implementing fall shelter systems could importantly declare these risks. Some fall shelter measures include:

- Guardrails: Install guardrails on most all open edges, including platforms and stairwells.

- Safety Nets: Place recourse nets below high working areas to catch falling objects or people.

- Harnesses: Workers of Electrical Estimating Services should have worn recourse harnesses when working at heights, and these should be secured to anchor point points.

A fall shelter is a base for workers performing tasks above the anchorperson even as it could preserve grievous injuries or fatalities.

Ensure Proper Use of Machinery and Equipment

Heavy machinery is based on building sites but can be grievous if not operated correctly. To check safety:

- Training: Only trained forces should have operated machinery.

- Maintenance: Regularly call and maintain all machinery to check it is in good working condition.

- Clear Zones: Establish designated areas with the most heavy sat where only authorized force is allowed.

- Lockout/Tagout Procedures: Ensure machines are shut off correctly and cannot be turned on while tending or repairing.

Using machinery safely and responsibly minimizes accidents involving equipment.

Monitor Site Conditions Regularly

The conditions on building sites changed frequently, and hazards could seem unexpected. It is based on regularly calling the site for any effectiveness risks. Some things to check include:

- Slippery Surfaces: Remove any water, oil, or other substances that could cause workers to slip.

- Loose Debris: Keep the site clean and free from materials that could cause trips or falls.

- Weather Conditions: Be aware of bold changes. For example, rain could slippery surfaces, and alcoholic winds could knock down sat or materials.

Constant wakefulness ensures that effectiveness hazards are addressed before they cause harm.

Follow Safe Lifting Practices

Improper lifting techniques could cause grievous back injuries. Workers should follow these guidelines when lifting heavy objects:

- Use Mechanical Aids: Whenever possible, use forklifts, cranes, and other sats to lift heavy loads.

- Bend at the Knees: When lifting manually,’ bend at the knees and not the waist to avoid straining your back.

- Team Lifting: If the accusative is too heavy for one person, ask for help and lift it with another worker.

- Know Your Limits: Don’t try to lift something too heavy or uncontrollable for you. Following meet-lifting practices helps protect workers from injury.

Maintained Clear Communication

Clear communication on building sites is based on ensuring everyone is aware of ongoing activities, effectiveness hazards, and exigency situations. Some ways to maintain good communication include:

- Hand Signals: Use received hand signals for machinery operators when communicating isn’t possible.

- Radios: Equip workers with radios to intercommunicate large or noisy sites.

- Safety Meetings: Hold daily or hebdomadally recourse briefings to keep everyone informed about effectiveness hazards and recourse procedures.

Good communication helps to prevent misunderstandings that could lead to accidents.

Control Access to the Site

Construction sites should be restricted to authorized forces only to minimize risks. Implement measures to check access, such as:

- Fencing: Erect fenced most of the border to preserve unauthorized entry.

- Security Personnel: Employ credentials guards to Saran the admittance and check that only authorized workers enter the site.

- Signal: Post clear signs for most of the site warning about hazards and restricted areas.

A controlling approach keeps untrained individuals away from grievous areas, reducing the risk of accidents.

Handle Hazardous Materials

Safely Many building sites use grievous materials, such as chemicals, asbestos, or ignitable substances. It’s based on dealing with these materials safely by following these steps:

- Storage: Store grievous materials in designated areas away from high-traffic zones.

- Labels: Clearly label all grievous substances to preserve misuse.

- PPE: Ensure workers handling grievous materials wear backlog PPE, such as gloves and masks.

- Training: Provide appropriate training for workers of Construction Estimating Services NYC on how to deal with and characterize grievous substances safely.

Proper handling of grievous materials prevents pic to grievous chemicals and reduces the risk of fires or contamination.

Conclusion

Construction sites were inherently dangerous, but with the right recourse measures in place,’ the risks can be greatly reduced. Wearing proper PPE, conducting firm training, maintaining equipment, and fostering a safety-first mindset are bases for preventing accidents and injuries. By following these recourse tips, building workers and managers can check that the site is a safe place to work for everyone involved.

ALSO READ: How a Smart Security System Enhances Automotive Safety