Table of Contents

- Types of Casters

- Assessing Load Capacity

- Wheel Materials and Floor Compatibility

- Environmental Considerations

- Maneuverability and Swivel Options

- Braking Systems and Safety Features

- Maintenance and Durability

- Final Thoughts

Enhancing mobility within industrial and commercial environments is critical for productivity and safety. Selecting the right casters can significantly affect how equipment, workstations, and storage units handle heavy loads or frequent movement. When assessing which caster is ideal for your needs, it’s essential to start by understanding the different options available, such as a phenolic wheel, and analyze how these integrate into your facility’s operational workflow. Making an informed choice reduces equipment downtime, increases safety margins, and can even prolong the lifespan of your flooring.

Identifying the correct caster also means decoding factors beyond just load bearing. Consider your environment’s specific requirements: Are the surfaces smooth or uneven? Is there exposure to moisture, chemicals, or high temperatures? Each scenario can dictate a unique solution. Investing in high-quality casters isn’t just about easing movement—it’s about enhancing efficiency and minimizing the risk of workplace accidents.

Types of Casters

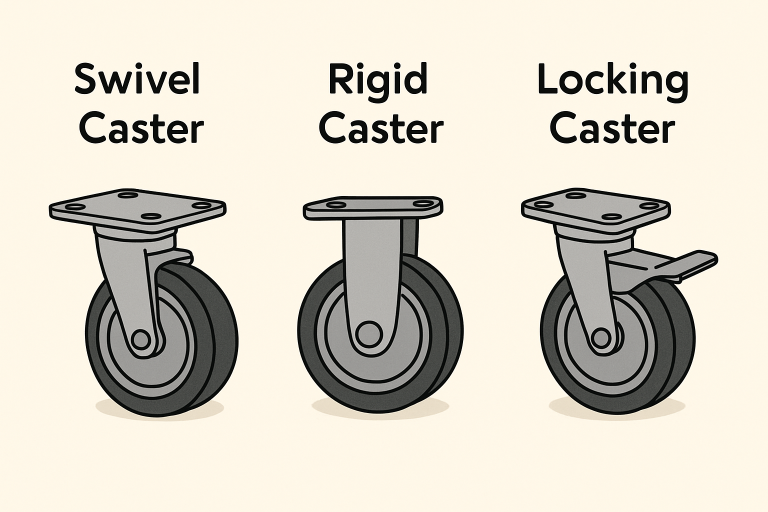

Casters are specialized wheels or assemblies that attach to the bottom of large objects, allowing them to move more freely. Typically, there are three main types:

- Swivel Casters: Rotate 360 degrees, perfect for tight or crowded spaces requiring maximum maneuverability.

- Rigid Casters: Offer fixed direction, ensuring precise straight-line travel. Common for equipment that doesn’t need to change direction often.

- Locking Casters: Feature brakes or locks that secure the wheel and sometimes the swivel mechanism, essential for safety during stationary tasks.

Knowledge of these varieties is fundamental when tailoring casters to specific tasks, such as loading docks, medical carts, or manufacturing lines.

Assessing Load Capacity

Each caster’s strength is determined by its load capacity, which is the maximum amount of weight it can reliably support. To calculate the requirement, take the total weight of the equipment and its proposed load, and divide this by the number of casters being used. It’s prudent to factor in a safety margin—choose casters that suit a higher load than the minimum needed, accounting for motion, shock, or uneven weight distribution. This approach aligns with recommendations from workplace safety authorities like OSHA.

Wheel Materials and Floor Compatibility

Wheel material directly impacts caster longevity, performance, and flooring integrity:

- Rubber Wheels: Known for quiet movement and shock absorption, rubber wheels are perfect for sensitive floor surfaces in hospitals or offices.

- Polyurethane Wheels: Durable and resistant to many chemicals, suitable across various floor types from factory to retail spaces.

- Steel Wheels: Offer unmatched load capacity, best used in warehouses with rough or uneven flooring where durability trumps noise considerations.

Matching the wheel to the right flooring prevents damage and facilitates smoother movement, as documented by Architectural Digest’s flooring guides.

Environmental Considerations

The setting in which your casters will operate can influence longevity and reliability:

- Temperature Extremes: In environments subjected to high heat or extreme cold, heat-resistant casters are a must to avoid failure under stress.

- Moisture and Chemicals: Workplaces exposed to water or chemicals—such as food processing or laboratory spaces—require corrosion-resistant casters, often made from stainless steel or specially coated materials.

Factoring in these environmental variables is crucial for safety, efficiency, and reduced maintenance costs.

Maneuverability and Swivel Options

How equipment is used often dictates the balance between maneuverability and stability. Swivel casters are favored when frequent direction changes are necessary, such as in tight corridors or assembly lines. Rigid casters are preferable for long, straight movement—such as moving heavy loads in warehouses. Many applications benefit from a hybrid approach, installing both swivel and rigid casters to offer versatility without compromising control.

Braking Systems and Safety Features

Brakes and safety mechanisms are critical, particularly in environments where stationary stability is vital. Foot-activated brakes are popular for easy engagement, especially on medical or laboratory carts. Directional locks keep casters rolling in one direction and are invaluable during transport across long distances. They also improve operator safety by preventing veering or unintended movement.

Maintenance and Durability

Routine maintenance is essential to keeping casters functional and extending their lifespan. Opt for sealed bearings that keep out debris and moisture, minimizing the need for frequent servicing. Regular checks for wear, flat spots, or misalignment prevent unexpected breakdowns and keep operations running smoothly. Well-maintained casters save money in the long term and support continuous productivity.

Final Thoughts

Choosing the ideal caster for your facility involves careful consideration of load requirements, operational environment, and equipment use. By matching caster type, material, and features to your specific conditions, you will boost safety, extend the lifespan of flooring and equipment, and ensure efficient, reliable movement in your industrial or commercial space.