Table of Contents

- Introduction

- Common Uses of Recycled Scrap Iron

- Economic Benefits of Scrap Iron Recycling

- Environmental Advantages

- Challenges in Scrap Iron Recycling

- Conclusion

Introduction

Often viewed as a byproduct with little value, scrap iron actually plays a crucial role as a significant asset in modern manufacturing and global economic systems. Most people think of scrap iron as simply leftover metal, but its potential extends far beyond waste. While traditional iron production relies heavily on expensive mining and extensive raw material extraction, scrap iron recycling offers a sustainable, cost-effective alternative with far-reaching benefits.

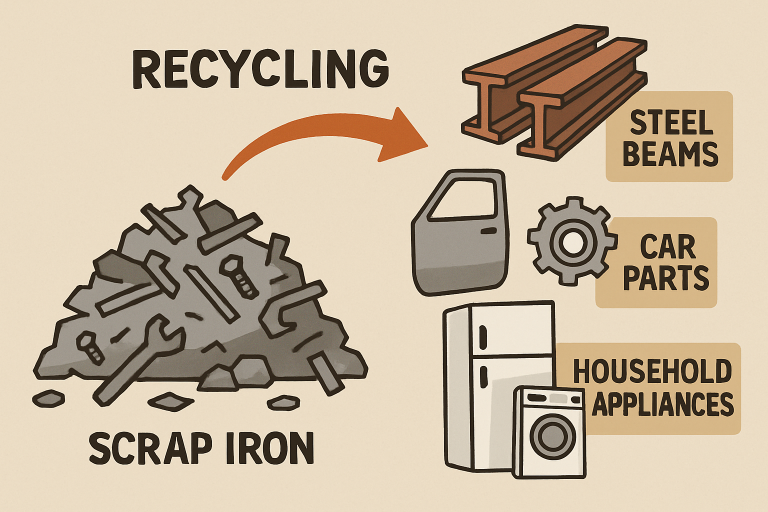

Recycling scrap iron transforms discarded materials, such as old machinery and vehicles, into new products, conserving natural resources and reducing landfill waste. So, what is scrap iron used for? It serves as a key raw material in the production of new steel products, including construction beams, automotive parts, appliances, and even tools. This versatility makes it indispensable across a range of manufacturing sectors, helping lower production costs while supporting environmental goals. This process supports global sustainability goals and has become vital across industries such as construction and automotive manufacturing, aided by government incentives that promote higher recycling rates. Beyond its economic benefits, recycled iron reduces the need for mining and cuts emissions, contributing to lower carbon footprints. However, maintaining efficient systems for collection, transport, and processing remains essential, requiring continued innovation and collaboration among industry and policymakers.

Common Uses of Recycled Scrap Iron

Construction Industry

One of the largest and most visible consumers of recycled scrap iron is the construction sector. Recycled iron is an essential component in the production of structural steel beams, reinforcing bars (rebar), girders, and other elements that form the backbone of bridges, skyscrapers, office complexes, and residential buildings. By utilizing recycled iron, the construction industry not only lessens its demand for freshly mined iron ore but also supports global efforts to make construction practices far more sustainable. In addition, using scrap rather than virgin iron ore reduces the energy typically required to extract, transport, and process these raw materials.

Automotive Manufacturing

The automotive sector is another major consumer of recycled scrap iron. Automakers routinely utilize recycled metals to manufacture structural components such as vehicle frames, axles, engine blocks, and various body panels. This practice not only provides manufacturers with a reliable, cost-effective supply of high-quality raw materials but also confers significant environmental advantages. Chief among these is the marked reduction in both energy consumption and carbon emissions along the entire automotive supply chain. By steadily increasing their use of recycled materials, car manufacturers can improve the sustainability profile of their vehicles and demonstrate their commitment to environmentally responsible production. Additionally, implementing recycled iron supports broader corporate social responsibility goals and helps automotive brands meet both regulatory and consumer demands for green innovation.

Appliance Production

Not to be overlooked, recycled iron also finds its way into everyday household appliances that millions of people rely on daily. Manufacturers of washing machines, refrigerators, stoves, dishwashers, and even small kitchen gadgets incorporate significant quantities of scrap iron into their products. The reliance on recycled materials is driven by factors such as cost efficiency, ready availability, and the growing importance of resource stewardship. By minimizing the need to extract and process newly mined iron ore, appliance manufacturers reduce their environmental footprint without compromising on performance or durability. In turn, these sustainable practices support broader industry efforts to lessen environmental impact and provide consumers with greener choices for their homes.

Economic Benefits of Scrap Iron Recycling

Job Creation

The scrap metal recycling sector is a cornerstone of job creation worldwide. Recycling operations sustain a vast array of professions, employing workers in areas such as the collection, transportation, sorting, and processing of metals, as well as logistics, equipment maintenance, and environmental compliance. In the United States alone, the recycling industry supports approximately 500,000 jobs—many of which are directly related to metal processing—offering stable, long-term employment in communities of all sizes. These jobs not only help stabilize local economies but also provide pathways to specialization, upskilling, and career development for a diverse workforce.

Revenue Generation

In addition to employment opportunities, scrap iron recycling is a powerful generator of economic activity. Globally, billions of dollars in value are generated every year through the buying, processing, and reselling of discarded iron and iron-based products. These activities create crucial new revenue streams, not just for prominent industrial recyclers but also for individuals who collect scrap, local businesses that trade in metal, and even municipalities that oversee and regulate recycling programs. As highlighted by the World Economic Forum, recycling metals represents an opportunity too good to waste, contributing not only to sustainability but also to strong and inclusive economic growth. By injecting this revenue into local and regional economies, the recycling industry helps foster economic resiliency, drive industrial growth, and support public infrastructure and services, all of which help position recycled scrap iron as a key driver of economic opportunity.

Environmental Advantages

Energy Conservation

Recycling iron scrap offers unparalleled advantages for energy conservation. Compared with traditional steelmaking processes, which start with virgin ore, recycling requires considerably less energy, both in raw extraction and in refining. The energy savings are not trivial: processing recycled iron can save up to 74% of the energy costs required to produce steel from scratch. According to the U.S. Energy Information Administration (EIA), recycling metals such as iron and steel significantly reduces overall industrial energy demand, helping to create a more efficient and sustainable energy landscape. These dramatic reductions in energy consumption lower greenhouse gas emissions, reduce stress on national energy grids, and make sustainable industrial operations more feasible.

Reduction of Greenhouse Gas Emissions

Another top-tier environmental benefit of recycling scrap iron is the significant reduction in greenhouse gas emissions. Manufacturing steel or iron products from mined ore is an energy-intensive process that generates substantial amounts of carbon dioxide and other polluting gases. In contrast, recycling scrap iron consumes far less energy and produces considerably fewer emissions. By reducing reliance on traditional mining and high-emission refining methods, the recycling industry plays a pivotal role in tackling climate change, helping countries and industries progress toward their national and international emissions-reduction commitments.

Challenges in Scrap Iron Recycling

Quality Control

Despite its obvious benefits, scrap iron recycling is not without challenges. One major challenge is maintaining the purity and consistency of recycled scrap iron, which is crucial for its effective reuse in high-performance and safety-critical applications. Residual contaminants or poor sorting can compromise the structural integrity and safety of the final products derived from recycled metals. This makes robust quality control practices essential at every stage of the recycling process to ensure recycled iron meets industry standards.

Market Fluctuations

Another significant hurdle is the inherent volatility of the scrap iron market, which is closely tied to global commodity prices. The price of recycled metals can fluctuate due to a variety of factors—ranging from supply and demand shifts, to changes in raw material availability, to the impact of international economic and geopolitical events. Such unpredictability can create uncertainty for both scrap recyclers and manufacturers, complicating efforts to secure stable supply contracts or plan budgets with confidence.

Conclusion

The recycling of scrap iron has become a fundamental pillar of sustainable economic development and environmental stewardship worldwide. With its wide array of industrial applications, substantial economic impact, and demonstrable environmental benefits, scrap iron is reshaping material sourcing strategies and supply chain operations for the better. Looking ahead, continued investments in recycling technology and system improvements will help industries maximize these benefits, ensuring that scrap iron remains a vital and valuable part of the modern circular economy for generations to come.